At OnDrive Inc., we provide professional VFD maintenance services to reduce downtime and extend the life of your control equipment. Our experienced technicians ensure every component is cleaned and tested for peak performance. Whether your facility relies on AC or DC, our VFD maintenance process addresses everything from performance to firmware stability.

We deliver scheduled and emergency VFD maintenance across all industries, ensuring regulatory compliance and reliable operations.

Industrial Drive Repair Services You Can Rely On

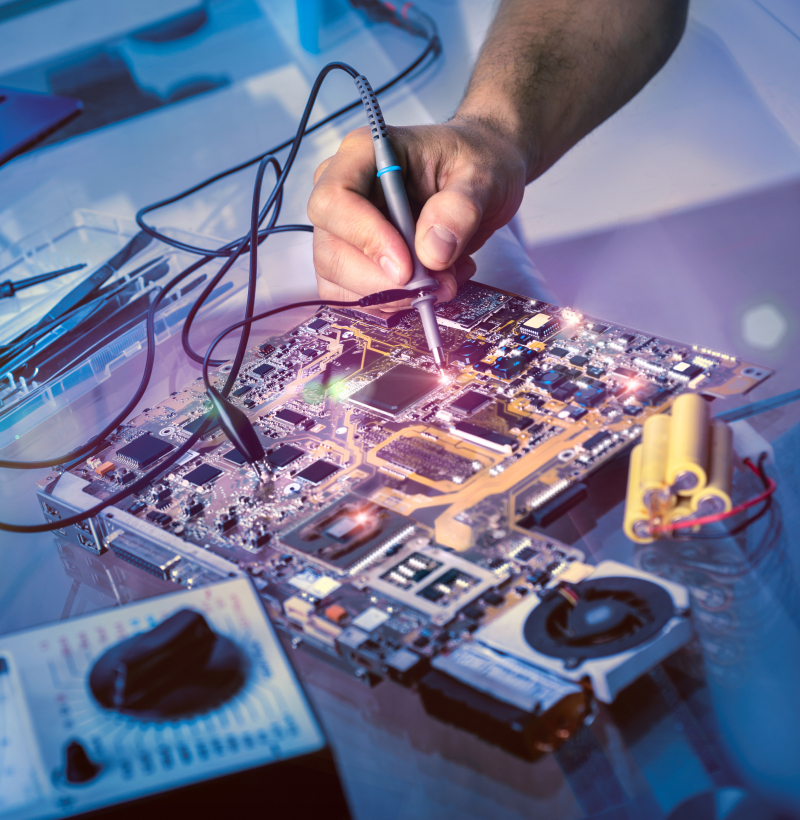

Our industrial drive repair solutions are tailored to heavy-duty manufacturing, food processing, elevator, HVAC, water treatment, agriculture, fan and pump control to conveyor system and logistics applications. These systems face complex demands, and our certified team handles issues like overheating, input faults, power inconsistencies, and drive failures.

With decades of experience in industrial drive repair, we perform advanced diagnostics and offer replacements or adjustments as needed to keep operations stable. From troubleshooting power stages to replacing damaged IGBTs, we ensure every AC drive repair is handled with minimal delay.

Reliable Variable Frequency Drive Maintenance

Routine variable frequency drive maintenance helps prevent equipment failure and prolongs system lifespan. Our services include capacitor testing, voltage monitoring, and real-time diagnostics.

Clients who invest in regular variable frequency drive maintenance see reduced downtime and extended life of their control equipment, lower energy bills, fewer disruptions, and more accurate control across their systems.

DC Drive Repair Services for Legacy and Specialty Equipment

Whether you use brushed DC motors or compound field designs, our DC drive repair covers everything from component testing to circuit board replacement. We understand the value of extending legacy equipment and offer support for hard-to-source parts.

Our team’s complete DC drive repair restores responsiveness, voltage stability, and compliance with control requirements in aging systems.

Expert Elevator Drive Repair Services

We provide fast and dependable elevator drive repair services for commercial buildings, hospitals, and multi-residential towers.

Each elevator drive repair thoroughly assesses each unit, cleans and tests VFD functions, ensuring proper drive function.

Our VFD Maintenance Services Include:

- Scheduled and emergency VFD maintenance

- Fan and capacitor inspections

- Firmware updates and drive tuning

- Component testing and diagnostics

- Technical reporting and recommendations